After using a tandem cable kit set that wasn’t quite long enough, Merry Sales’ Jim Porter kindly helped identify Rohloff Shifter Cable Set 63640 (UPC 0899430044112) to get my Rohloff twist shifter mated with a Speedhub 500/14 on my XL frame Big Dummy, which requires a bit extra length.

Prior to this post, my Dummy had Rohloff shift housing and cables installed, which are adequate, but after enjoying Yokozuna’s strong Reaction brake housing and cables I knew I had to try their shift housing and cables. On the Big Dummy’s long cable run, the compressionless brake housing brings responsiveness I haven’t seen in other housings and I’m hoping for something similar with Yokozuna’s shift housing and cables.

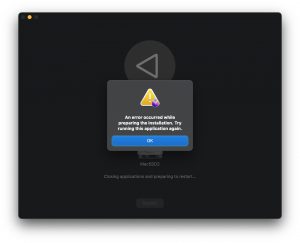

Installation goes just like any other cable and I used Rohloff’s how-to video for installing the cables to the twist shifter and supplementary video for an external mech setup.

First thing I noticed after pulling the Yokozuna Shifter Cable Set from the packaging is that the housing has a smaller diameter than Rohloff’s cables, so much that I had to measure the difference: Rohloff housing has a 4.8 mm diameter and Yokozuna has a svelte 4.1 mm diameter. I didn’t weigh the two, but I’d expect a difference.

To fit the cable housing to the Dummy, I ended up cutting 50 mm of housing from the lengths provided by Yokozuna, I aimed for twin 2250 mm housing lengths and this proved useful, as I later had to switch the cable positions around and cut off another centimeter.

After getting the cables on the Dummy in my shop and running through the gears, I can already say I’ve never felt my Rohloff shift through gears this smoothly. I’ll verify this with the Dummy out on the road tomorrow and come back with an update, but I’m already tickled to now have Yokozuna on my front brake and shifter. Note, a future post might be when I’m able to return Yokozuna to the rear brake, which is where the most noticeable benefit is seen on this bike – I expect to do this when I replace the rear caliper after this winter.

I’ll pass this back to Merry Sales, but the set includes cable caps and these are superfluous to Rohloff internal and external mechs.

** Update 12-4-2020 **

I’ve ridden the Dummy a few times now and will re-state how smooth and easy shifting is with Yokozuna shift housing and cables. I’m hoping this holds up!